|

|

|

|

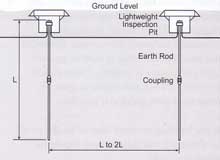

Parallel earth rod electrodes |

|

Where ground conditions make deep driving of earth rods impossible, a matrix arrangement of rods coupled to one another by conductors can be used. If possible, the earth rods must be spaced at a distance at least equal to their driven depth. If earth rods cannot be driven in a parallel line a "Crows Foot" configuration can be used, ensuring that the spacing/depth ratio is still maintained. High resistivity soil conditions can be overcome by backfilling earth rods with a suitable medium such as Marconite conductive concrete which effectively increases the diameter of the earth rod and hence its surface area, thus lowering resistance to earth.

| |

| Bonding | |

|

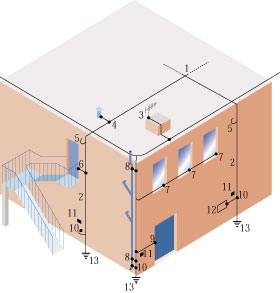

All metal work, including water pipes, gas pipes, handrails, air conditioning units, metal cladding, metal roofs etc, in the vicinity of the LPS must be bonded to it, to avoid the danger of side flashing. For the same reason, the LPS earth should be bonded to the main electrical earth, as well as any other earthing system present in the structure. | |

| If the lightning protection system on a structure is hit by lightning, then the current flowing through the system and the resistance/impedance offered by the conductor path will determine the magnitude of the potential difference seen by the lightning conductors with respect to true earth. The lightning conductors can, instantaneously, have a potential magnitude of megavolts (1,000,000V) with respect to true earth. Typically, at instant of discharge: |

| Figure 8 - Bonding to prevent side flashing 1 Air termination |

|

| |