|

|

|

|

|

|

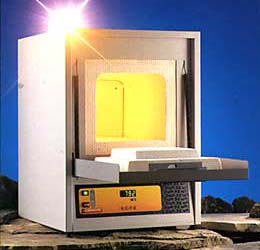

for loading and unloading

|

| Introduction | |

| These furnaces - comprising the ELF, EML and EAF form a range of economy furnaces with a maximum operating temperature of 1100°C. Whilst the EAF and EAF are suitable for light duty general laboratory work, the EML is more robust. All models are offered with digital three term controllers. The drop down door can be used as a shelf when loading and unloading samples. The door plug also acts as a trap for radiated heat, |

thus improving the chamber uniformity,whilst the air gap behind the plug minimises the external door temperature. Safety features on all models include a positive break

safety switch which isolates both power lines to the heating elements

when the door is opened. Low case temperatures are achieved by using

double skin construction to promote natural air convection. |

| |

|

|

ELF models The innovative design of the ELF range, with capacities of 6 and 14 litres, features a one piece moulded ceramic fibre chamber with integral heating elements. They offer exceptional performance with traditional quality and reliability. The heating elements are positioned in the sides and roof of the vacuum formed chamber - elements are not located in the hearth to prevent damage from accidental spillage. For additional protection, a hard ceramic hearth tile is available as an option. These models offer fast heat up - 900°C is achieved

in less than 15 minutes. Low thermal mass insulation materials ensure

maximum thermal efficiency and allow rapid heating and cooling. Fumes

are extracted from the chamber via a ceramic chimney. |

EAF models

The economy ashing furnace is of the same construction as the ELF and offers the same chamber dimensions and temperature range, with the addition of a tall chimney to improve the air flow through the chamber for faster burning or drying of the samples. In conjunction with the tall chimney, additional ventilation is provided by air inlets located in the bottom of the door plug - air is drawn through the inlets and up through the chimney. The EAF is suitable for ashing only small samples and it is recommended that samples with no more than 50g of carbon content should be ashed. The addition of the chimney can extend the life of the heating elements by rapid removal of reactive products which could attack the heating element wire. For large volume ashing requirements, please refer to the

Ashing & Burn Off Furnaces section. |

| |

|

|

EML model

This model is housed in the same outer case as the ELF and is available with a capacity of 2.5 litres and a maximum temperature of 1100°C. The robust muffle is formed from high thermal mass refractory and is wound with resistance wire whiich heats the chamber from four sides. The traditional muffle element design combines good

temperature uniformity with durability and offers greater protection

to the heating elements. |

|

| Specifications |

|

| Model | ELF 11/6 | ELF 11/14 | EML 11/2 | EAF 11/6 | EAF 11/14 |

| Max Temp (°C) | 1100 | 1100 | 1100 | 1100 | 1100 |

| Chamber Dimensions (mm) (H) (W) (D) |

165 180 200 |

210 220 300 |

90 150 185 |

165 180 200 |

210 220 300 |

| External Dimensions (mm) excluding chimney (H) (W) (D)

|

580 410 410

|

630 450 520

|

580 410 410

|

580 410 410

|

630 450 520

|

| Chamber capacity (litres) | 6 | 14 | 2.5 | 6 | 14 |

| Max Power (W) | 2000 | 3000 | 1750 | 2000 | 3000 |

| Holding Power (W) | 800 | 1300 | 600 | 1100 | 1700 |

| Heat Up Time (mins) to 100°C below max |

12 | 13 | 65 | 14 | 16 |

| Air changes per minute | N/A | N/A | N/A | 4 | 2 |

| Temperature Sensor | K | K | K | K | K |

| Weight (kg) | 18 | 26 | 20 | 18 | 26 |