| | |

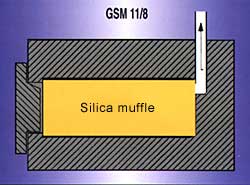

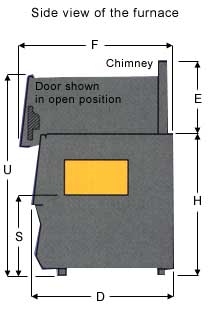

| Model | AAF 11/3 | AAF 11/7 | AAF 11/18 | GSM 11/8 |

|

| Max Temp (°C) | 1100 | 1100 | 1100 | 1100 | |

| Internal Dimensions (mm) (H) (W) (D) | 85 150 250 | 90 170 455 | 235 196 400 | 120 175 345 | |

| External Dimensions (mm) (see diagram opposite) (H) (W) (D) (U) (F) (E) (S) | 580 370 485 795 545 200 320 | 650 430 740 895 815 410 370 | 705 505 675 1005 755 200 320 | 705 505 725 1000 805 45 365 | |

| Nett Weight (kg) | 22 | 63 | 70 | 59 | |

| Max Power (watts) | 1750 | 3900 | 7250 | 3000 | |

| Holding Power (watts) | 1200 | 2300 | 3500 | 1200 | |

| Nominal Heat Up Time (mins) | 80* | 110* | 60 | 90 | |

| Uniform Envelope (mm) (at 800°C +/-10°C) (H) (W) (D) | 50 100 100 | 55 140 260 | | 85 135 280 | |

| Temperature Sensor | Type K thermocouple | ||||

| Electrical Supply Options | 1 phase | 1 phase 2 phase | 1 phase Universal | 1 phase | |

| * Estimated performance | |||||