| | |

| |

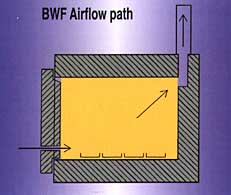

| These are models heated by free radiating coiled wire heating elements housed in a high quality alumina bases hard wearing element carrier. With the use of graded winding, the elements compensate for heat loss and optimise temperature uniformity within the chamber. The elements are located in the sides only and so are protected from contamination by accidental spillage. Hard wearing refractories around the chamber entrance and in the chamber base provide excellent resistance to everyday wear and tear. Airflow is enhanced in the BWF model by the addition of a tall chimney and air inlet holes in the door which rapidly remove the fumes from the furnace, preventing carbon deposits forming. The CWF is ideal for burn-off or ashing of natural materials such as natural fibres and cereal food stuffs such as wheat flour, milk powder and soya, depending on the size of sample. If a large sample is required then a BWF may be more suitable. The BWF is ideal for cleaning processes such as removing wax from ceramic moulds. |  BWF 12/13/201

|

| | |

| Model | CWF 11/13 | CWF 12/13 | BWF 11/13 | BWF 12/13 |

|

| Max Temp (°C) | 1100 | 1200 | 1100 | 1200 | |

| Internal Dimensions (mm) (H) (W) (D) | 200 200 325 | 200 200 325 | 200 200 325 | 200 200 325 | |

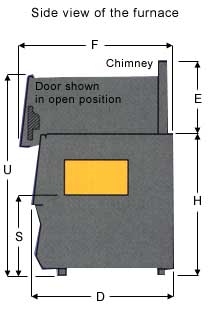

| External Dimensions (mm) (see diagram) (H) (W) (D) (U) (F) (E) (S) | 655 435 610 905 895 145 320 | 655 435 610 905 895 145 320 | 655 435 610 905 895 145 320 | 655 435 610 905 895 145 320 | |

| Max Power (watts) | 3100 | 7250 | 3100 | 3100 | |

| Holding Power (watts) | 1300 | 1550 | 1500 | 1700 | |

| Nominal Heat Up Time (mins) | 55 | 65 | 60 | 70 | |

| Uniform Envelope (mm) (+/-5°C) (H) (W) (D) | 120 120 185 | 120 120 200 | 120 120 185 | 120 120 185 | |

| Temperature Sensor | Type K thermocouple | ||||