| Earthing Lightning Protection | |

|

|

|

| |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A correctly designed and installed earthing system will sageguard both lives and equipment. A good earth connection should have: Soil resistivity is a crucial factor in obtaining a 'good earth'

Factors Affecting Soil Resistivity a ) Physical Composition Different soil compositions give different average resistivities:

b ) Moisture Increased moisture content of the ground can rapidly decrease its resisitivity. It is especially important to consider moisture content in areas of high seasonal variation in rainfall. Wherever possible the earth electrode should be installed deep enough to reach the "water table". or "permanent moisture level".

c ) Chemical Composition Certain minerals and salts can affect soil resistivity. Their levels can vary with time due to rainfall or flowing water.

|

|

Note that although the addition of salt can lower soil resistivity, they are not recommended due to corrosion and leaching. c ) Temperature When the ground becomes frozen, its resistivity rises dramatically. An earth that may be effective during temperate weather may become ineffective in winter.

Please note that, if your soil temperature decreases from +20°C to -5°C, the resistivity increases more than ten times.

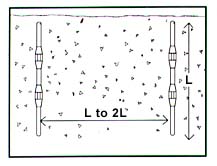

Selecting the Correct Earth Electrode By reaching permanent moisture and frost free soil levels, low resistance should be achieved. Often these levels are some metres below the surface and the most economical way of reaching them is by extensible deep driven earth rod electrodes. Furse recommend the use of deep driven earth rod electrodes wherever conditions allow. Where rocks lie just below the surface and deep driving is not possible, parallel driven shorter rods, plates, mats or buried conductors, or a combination of these can be used. However, these should still be buried as deep as possible to avoid seasonal variations, damage from agricultural machinery etc. Often parallel rods are driven too close together; this decreases their effectiveness. The distance between rods should be greater than the rod length, L (see diagram below).

Earth Rod Electrodes Quality earth rods are commonly made from either solid copper, stainless steel or copperbonded steel. Furse manufacture all three types, but the copperbonded steel cored rod is by far the most popular, due to its combination of strength, corrosion resistance, and comparatively low cost. Solid copper and stainless steel rods offer a very high level of corrosion resistance at the expense of lower strength and higher cost. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Earthing Lightning Protection | |