|

Home › Laboratory › Furnaces, Ovens & Incubators › Nabertherm

High-Temperature Furnaces

High-Temperature Furnaces HTC with SiC Rod Heating as Table-Top Model

HTC 03/14 - HTC 08/16

These powerful laboratory muffle furnaces are available for temperatures up to 1400 °C, 1500 °C, or 1600 °C. The durability of the SiC rods in periodic use, in combination with their high heating speed, make these furnaces to all-rounders in the laboratory. Heating times of 40 minutes to 1400 °C can be achieved, depending on the furnace model and the conditions of use.

Tmax 1400 °C, 1500 °C, or 1600 °C Tmax 1400 °C, 1500 °C, or 1600 °C

Easy replacement of heating rods Easy replacement of heating rods

High-quality fibre material, selected for the working temperature High-quality fibre material, selected for the working temperature

Casing made of sheets of textured stainless steel (non-rusting design) Casing made of sheets of textured stainless steel (non-rusting design)

Double-walled casing for low external temperatures and high stability Double-walled casing for low external temperatures and high stability

Optional fold-down door which can be used as work platform or lift door with hot surface facing away from the operator Optional fold-down door which can be used as work platform or lift door with hot surface facing away from the operator

Adjustable air intake opening in the furnace door, exhaust air opening in the back wall Adjustable air intake opening in the furnace door, exhaust air opening in the back wall

Switching system with semiconductor relay, power tuned to the SiC rods Switching system with semiconductor relay, power tuned to the SiC rods

Additional Equipment

Over-temperature limit controller with adjustable cutout temperature for thermal protection class in accordance with EN 60519- as temperature limiter to protect the oven and load

Models in this range include the HTC 03/14, HTC 08/14, HTC 03/15, HTC 08/15, HTC 03/16 and HTC 08/16. Models in this range include the HTC 03/14, HTC 08/14, HTC 03/15, HTC 08/15, HTC 03/16 and HTC 08/16.

High-Temperature Furnaces LHT with MoSi2 Heating Elements as Table-Top Model

Designed as tabletop models, these compact high-temperature furnaces have a variety of advantages. The first-class workmanship using high-quality materials, combined with ease of operation, make these furnaces all-rounders in research and the laboratory.

These furnaces are also perfectly suited for the sintering of technical ceramics, such as zirconium oxide dental bridges.

|

Tmax 1600 °C, 1750 °C, or 1800 °C Tmax 1600 °C, 1750 °C, or 1800 °C

High-quality molybdenum disilicide heating elements High-quality molybdenum disilicide heating elements

Furnace chamber lined with first-class, durable fibre material Furnace chamber lined with first-class, durable fibre material

Casing made of sheets of textured stainless steel (non-rusting design)Double-walled casing with additional cooling using fans, for low exterior temperature Casing made of sheets of textured stainless steel (non-rusting design)Double-walled casing with additional cooling using fans, for low exterior temperature

Furnace sizes of 2, 4, or 8 litres Furnace sizes of 2, 4, or 8 litres

With lift door, whereby the hot side is away from the operator With lift door, whereby the hot side is away from the operator

Exhaust air opening in the roofType B thermocouple Exhaust air opening in the roofType B thermocouple

Switching system with phase-angle firing thyristors (SCRs) Switching system with phase-angle firing thyristors (SCRs)

Additional Equipment

|

|

|

|

Over-temperature limit controller

|

|

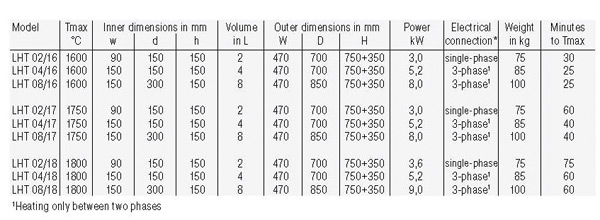

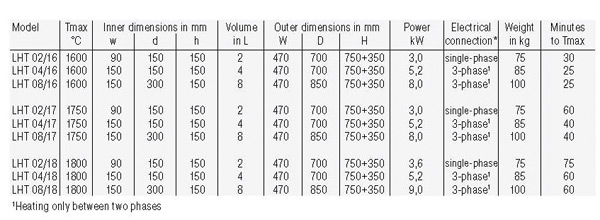

Models in this range include the LHT 02/16, LHT 04/16, LHT 08/16,

LHT 02/17, LHT 04/17, LHT 08/17, LHT 02/18, LHT 04/18 and LHT 08/18. Models in this range include the LHT 02/16, LHT 04/16, LHT 08/16,

LHT 02/17, LHT 04/17, LHT 08/17, LHT 02/18, LHT 04/18 and LHT 08/18.

High-Temperature Furnaces HT with MoSi2 Heating Elements as Floor Models

|

|

|

Gas supply panel for nonflammable protective gas with shutoff valve and flow meter with regulator valve, piped and ready to connect

|

|

| Automatic Vent Flap |

|

Models in this range include the HT 04/16, HT 08/16, HT 16/16, HT 32/16, HT 40/16, HT 64/16, HT 128/16, HT 160/16, HT 276/16, HT 450/16, HT 04/17, HT 08/17, HT 16/17, HT 32/17, HT 40/17, HT 64/17, HT 128/17, HT 160/17, HT 276/17, HT 450/17, HT

04/18, HT 08/18, HT 16/18, HT 32/18, HT 40/18, HT 64/18, HT 128/18, HT 160/18, HT 276/18 and HT 450/18. Models in this range include the HT 04/16, HT 08/16, HT 16/16, HT 32/16, HT 40/16, HT 64/16, HT 128/16, HT 160/16, HT 276/16, HT 450/16, HT 04/17, HT 08/17, HT 16/17, HT 32/17, HT 40/17, HT 64/17, HT 128/17, HT 160/17, HT 276/17, HT 450/17, HT

04/18, HT 08/18, HT 16/18, HT 32/18, HT 40/18, HT 64/18, HT 128/18, HT 160/18, HT 276/18 and HT 450/18.

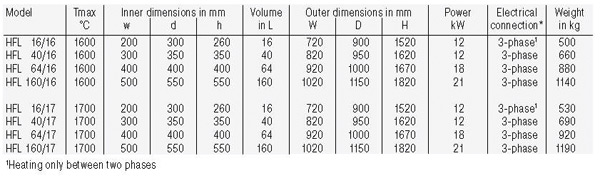

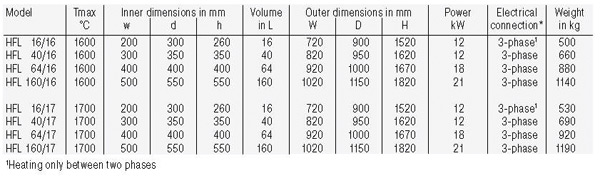

High-Temperature Furnaces HFL as floor Models with Brick Insulation for Melting Experiments

HFL 16/16 - HFL 160/17

The HFL 16/16 - HFL 160/17 series is particularly characterized by their special cladding with light refractory bricks. This insulation is necessary when aggressive gasses (such as vapourized glass) or acids may be produced in the process.

Tmax 1600 °C or 1700 °C Tmax 1600 °C or 1700 °C

High-quality molybdenum disilicide (MoSi2) heating elements High-quality molybdenum disilicide (MoSi2) heating elements Insulation with light refractory bricks and special backup insulation Insulation with light refractory bricks and special backup insulation

Type B thermocouple Type B thermocouple

Furnace sizes of 16 to 160 litres Furnace sizes of 16 to 160 litres

For the release of vapours, a 30 mm large exhaust hole is integrated into the roof of the furnace For the release of vapours, a 30 mm large exhaust hole is integrated into the roof of the furnace

Over-temperature limit controller for protection of material Over-temperature limit controller for protection of material

Models in this range include the HFL 16/16, HFL 40/16, HFL 64/16, HFL 160/16, HFL 16/17, HFL 40/17, HFL 64/17 and HFL 160/17. Models in this range include the HFL 16/16, HFL 40/16, HFL 64/16, HFL 160/16, HFL 16/17, HFL 40/17, HFL 64/17 and HFL 160/17.

Please note - Product designs and specifications are subject to change without notice. The user is responsible for determining the suitability of this product.

|