| |

|

|

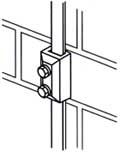

Down conductors |

|

Earth termination networks Each

down conductor must have a separate earth termination. Moreover

provision should be made in each down conductor, for disconnection from

the earth for testing purposes.This is achieved with a test clamp (see

Figure 4). | ||

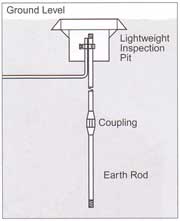

Figure 4 - Oblong test or junction clamp | BS 6651 stipulates that the resistance to earth of the lightning protection system measured at any point, should not exceed 10 ohms. With the test clamp disconnected, the resistance of each individual earth should be no more than ten times the number of down conductors in the complete system. eg for a system with 15 down conductors, the individual earth readings should be no more than 10 x 15 = 150 ohms. Several types of earth electrode are permissible, but by far the most commonly used are deep driven earth rods. BS 6651 states that the combined earth rod length of a system should be no less than 9m whilst each individual earth rod should be no less than 1.5m in length.

|  Figure 5 - Deep driven earth electrode |

| |